We generally continually give you quite possibly the most conscientious shopper company, and the widest variety of designs and styles with finest materials. These endeavours include the availability of customized designs with speed and dispatch for China OEM Pe Plastic Pipe Production Line List Pe Pipe Machine, Our workforce members are intention to provides products and solutions with large performance cost ratio to our shoppers, as well as the goal for all of us would be to satisfy our consumers from everywhere in the globe.

We generally continually give you quite possibly the most conscientious shopper company, and the widest variety of designs and styles with finest materials. These endeavours include the availability of customized designs with speed and dispatch for Pe Pipe Machine, pe pipe production line, Plastic Pipe Production Line, Our R&D department always designs with new fashion ideas so we could introduce up-to-date fashion styles every month. Our strict production management systems always ensure stable and high quality goods. Our trade team provides timely and efficient services. If there are any curiosity and inquiry about our products, remember to contact us in time. We would like to establish a business relationship with your honored company.

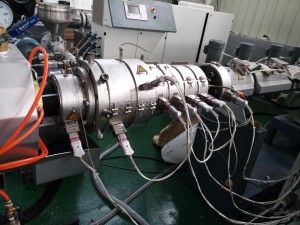

1.Machine introductions for PP PE PPR pipe production line:

Application of pe pipe:

With the PE pipe production line, you can extrude high quality large diameter water and gas supply pipes .This pipes produced by our line have excellent stiffness and flexibility ,resistance to creep deformation ,excellent heat-linkage .Large dismeter HDPE pipes start to play very important role in the city water and gas supply systems.

Machine advantages of pe pipe production line :

This line is assembled lattice or spiral mould, new type calibration unit and spraying cooling bath. Advanced PLC control system and large chromatic liquid-crystal screen make the operation more convenient ,having a friendly human-machine interface.

2. different models of PP PE PPR pipe production line for different diameter:

| Model | Diameter(mm) | Marking line machine model | Max.output(kg/h) |

| SJ-65B | φ110 | SJ-25 | 90-180 |

| SJ-90B | φ200 | SJ-30 | 200-320 |

| SJ-120B | φ400 | SJ-30 | 320-500 |

| SJ-150B | φ630 | SJ-30 | 550-700 |

3, Machine line consists of PE pipe production line:

The production line consists of control system ,extruder,mould,calibration unit,haul-off unit,planetary cutter and stacker.

1, Main extruder: single screw extruder

2, co-extruder: SJ30 extruder for marking line

3, die head: different size may use different die head

4, vacuum cooling tank: 6 meter length

5, spraying water tank: 6 meter length, for big diameter, we may need to equip 2 sets or 3 sets of spraying water tank

6, haul off machine: for different diameter, we may equip different type of haul off machine, such as double caterpillar type, three caterpillar type, four caterpillar type

7, cutting machine: high quality cutting machine for non-dust cutting

8. product stacker: 6 meter length

1, WARRANTY TERMS:

1.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

1.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

1.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

2, DELIVERY CONDITIONS:

2.1 DELIVERY CONDITION: FOB QINGDAO PORT.

2.2 DELIVERY TERM: WITHIN 60 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

2.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER CAN ARRANGE FOR SUPERVISION OF LOADING.

3, INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4, INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE.

If any interest to our machines, please kindly feel free to contact us:

Email: info@tongsanextruder.com info@wpcmachinery.com

Phone: 0086-13953226564

TEL:0086-532-82215318

Address: The West End And South Side Of Yangzhou Road,Jiaozhou City,Qingdao,China

-

Supply ODM China Continuous Type Bright Anneali...

-

Good quality Cold steel three layer roll formin...

-

Manufacturer for Active Pvc Foam Board Producti...

-

Hot-selling China Acrylic Sheet/Wood/Leather/Cl...

-

ODM Factory Pvc Cpvc Upvc Hdpe Pe Plastic Water...

-

Good quality China WPC UPVC Outside Wall Panel ...