Chinese Professional Pvc Spiral Hose Making Machine - 600-1600mm Filter material melt blown machine pp non woven fabric making machine – HEGU Detail:

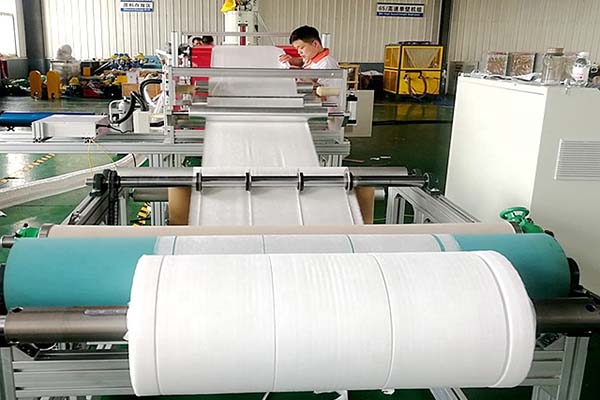

600-1600mm Filter material melt blown machine pp non woven fabric making machine

Quality of Hegu PP melt blown fabric making machine

1, The filtrability of PP melt blown fabric made by our machine can be more than PFE95+.

2, The fltrability of PP melt blown fabric made by our machine is very stably to be PFE95+ even tested after many days.

3, our machine can make stably production for high quality PP melt blown fabric with filtrability more than PFE95+

Application of PP melt blown fabric

Melt-blown non-woven fabric is a kind of rapid development in the production of non-woven fabric. It is known as the one-step polymer production process with the shortest process abroad. Its products have many obvious advantages such as high filtration efficiency, low resistance, flexibility, and the network can bind and bond itself. Therefore, it is widely used in various countries, and its main uses are medium-efficiency and sub-efficiency filtration, including air filtration and acid destruction. Liquid filtration food hygiene filtration, industrial dust mask manufacturing, etc., in addition, can also be used as medical and hygiene products, industrial precision wipes, thermal insulation materials, oil-absorbing materials, battery separators, imitation leather base cloth and so on. In many ways, its performance is better than similar products of traditional textiles. With the continuous development of post-processing technology, the application fields of melt-blown non-woven fabrics will be more extensive.

1. Application in the field of air purification Used in air purifiers, as a sub-efficient and efficient air filter element, and for coarse and medium-efficiency air filtration at large flow rates. It has the advantages of low resistance, high strength, excellent acid and alkali resistance, corrosion resistance, stable efficiency, long service life and low price. There is no fluff in the gas purified by the filter.

2. Application in the field of medical and health The dust-proof mouth made of melt-blown cloth has small breathing resistance, no sulking, and the dust-proof efficiency is as high as 99%. It is widely used in hospitals, food processing, mines and other workplaces that require dust and anti-bacterial products after special treatment. The anti-inflammatory and analgesic film made has good breathability, no toxic and side effects, and is easy to use. SMS products combined with spunbond cloth are widely used in the production of sanitary products such as surgical clothes and hats. 3. Liquid filter material and battery separator Polypropylene meltblown cloth is used to filter acidic and alkaline liquids, oil, oil, etc. It has very good performance, has been regarded as a good separator material by the battery industry at home and abroad, and has been widely used, not only reduces battery costs, The process is simplified, and the weight and volume of the battery are greatly reduced.

4. Oil-absorbing materials and industrial wipes Various oil-absorbing materials made of polypropylene melt-blown cloth can absorb oil up to 14-15 times its own weight. It is widely used in environmental protection projects and oil-water separation projects. In addition, it can be used as a clean material for oil and dust in industrial production. These applications have fully utilized the characteristics of polypropylene itself and the adsorption of ultrafine fibers produced by meltblown.

5. Warm materials The average diameter of melt-blown ultrafine fibers is between 0.5 and 5m, the specific surface area is large, a large number of fine pores are formed in the cloth, and the porosity is high. A large amount of air is stored in this structure, which can effectively prevent heat loss, and has excellent thermal insulation, and is widely used in the production of clothing and various insulation materials. Such as leather jackets, ski shirts, cold clothes, cotton village cloth, etc., it has the advantages of light weight, warmth, no moisture absorption, good breathability, no moldy rotten.

Product detail pictures:

Related Product Guide:

Acrylic Plastic Sheets

PVC Pipes – Types of PVC Pipes and Their Usage

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for Chinese Professional Pvc Spiral Hose Making Machine - 600-1600mm Filter material melt blown machine pp non woven fabric making machine – HEGU, The product will supply to all over the world, such as: Haiti, Greenland, Armenia, we sincerely hope to establish a good and long-term business relationship with your esteemed company through this opportunity, based on equality, mutual benefit and win-win business from now to the future. Your satisfaction is our happiness.

1, WARRANTY TERMS:

1.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

1.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

1.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

2, DELIVERY CONDITIONS:

2.1 DELIVERY CONDITION: FOB QINGDAO PORT.

2.2 DELIVERY TERM: WITHIN 60 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

2.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER CAN ARRANGE FOR SUPERVISION OF LOADING.

3, INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4, INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE.

If any interest to our machines, please kindly feel free to contact us:

Email: info@tongsanextruder.com info@wpcmachinery.com

Phone: 0086-13953226564

TEL:0086-532-82215318

Address: The West End And South Side Of Yangzhou Road,Jiaozhou City,Qingdao,China

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.

-

High definition Acrylic Sheet Production Linel ...

-

OEM/ODM Factory Pvc Pipe Belling Machine - Pla...

-

China Gold Supplier for Machine To Make Pvc Mar...

-

High Quality for Profile Extrusion Plant - Pla...

-

Hot sale Pvc Profile/pipe/sheet Extrusion Line ...

-

Factory Promotional Wpc Profile Machine - PVC ...