Good Quality Single Screw Barrel - Plastic recycling machine PP PE PS PC ABS cold granulating production line – WOOD-PLASTIC Detail:

Plastic cold cut granulating production line

Brief Introduction

This machine line is mainly used for plastic with high melt index and high viscosity such as PP,PE,PS,HIPS,ABS,PC etc.It adopts parallel double screw extruder and single screw extruder,the specially designed screw is applicable to the granulating ,dyeing.reproduction for various materials.Hob cutting type granule cutter is characterized by stable rotation,

even cutting ,energy and electricity saving and safely operating etc.

We can make different types extruder according to the customized production output.

The specially design mould makes the granules more even.

The specially designed blade and hardening treatment make the lifespan of the equipment longer.

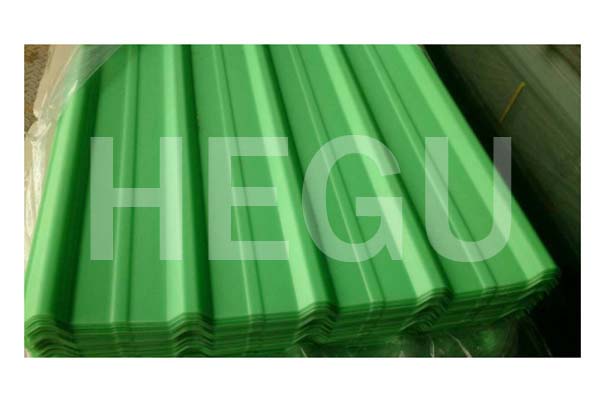

Product detail pictures:

Related Product Guide:

Acrylic Plastic Sheets

The Insider Scoop on a Vacuum Formable Plastic Sheet

Fast and great quotations, informed advisers to help you choose the correct solution that suits all your requirements, a short creation time, responsible high quality manage and distinct providers for paying and shipping affairs for Good Quality Single Screw Barrel - Plastic recycling machine PP PE PS PC ABS cold granulating production line – WOOD-PLASTIC, The product will supply to all over the world, such as: Singapore, Bahrain, Finland, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We've got tightened inspection for quality of product.

1, WARRANTY TERMS:

1.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

1.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

1.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

2, DELIVERY CONDITIONS:

2.1 DELIVERY CONDITION: FOB QINGDAO PORT.

2.2 DELIVERY TERM: WITHIN 60 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

2.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER CAN ARRANGE FOR SUPERVISION OF LOADING.

3, INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4, INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE.

If any interest to our machines, please kindly feel free to contact us:

Email: info@tongsanextruder.com info@wpcmachinery.com

Phone: 0086-13953226564

TEL:0086-532-82215318

Address: The West End And South Side Of Yangzhou Road,Jiaozhou City,Qingdao,China

The company keeps to the operation concept scientific management, high quality and efficiency primacy, customer supreme, we have always maintained business cooperation. Work with you,we feel easy!

-

Cheap PriceList for Pvc Garden Hose Making Mach...

-

Europe style for Pvc Trunking Profile Productio...

-

Bottom price Extusion Plastic Machinery - PVC ...

-

Original Factory Pe Pipe Pushing Machine - Woo...

-

8 Year Exporter Model Of Internal Doors - PVC ...

-

Factory directly Pipe Extrusion Line - PVC she...