OEM manufacturer Thick Sheet Extrusion Machine - Plastic recycling machine PPpe washing crushing drying line – WOOD-PLASTIC Detail:

PP PE washing/crushing/drying line

General information

1) Capacity: 300-400kg/h

2) Voltage required: 380V 50HZ 3P or as per client’s requests

3) Machine plate color: May as per client’s requests

Machine list and total price

|

No. |

Machine Name |

Qty |

| Belt conveyer | 1set | |

| Crusher with water | 1 set | |

| Screw conveyer | 1 set | |

| Friction washer | 1 set | |

| Floating washing tank | 1 set | |

| Screw conveyer | 1 set | |

| Dewatering machine | 1 set | |

| Silo | 2 set | |

| Electrical panel | 1 set |

Brief Introduction

HGMS series plastic cleaning machine is designed to clean recycled plastic woven sack and plastic farm film,the machine is widely used for PP,PE,PET plastic cleaning and plastic bottle cleaning,Developing on the basis of advanced technology,the machine has advantage of stable performance,high output,energy efficiency,small floor area and good appearance,We can produce the machine according to client requirement.

Layout drawing

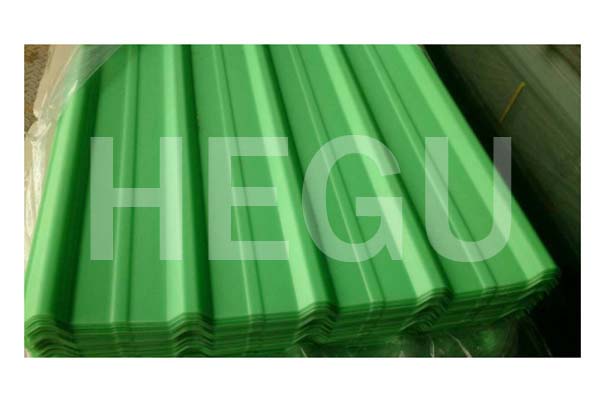

Product detail pictures:

Related Product Guide:

The Insider Scoop on a Vacuum Formable Plastic Sheet

PVC Pipes – Types of PVC Pipes and Their Usage

To create much more price for clients is our company philosophy; purchaser growing is our working chase for OEM manufacturer Thick Sheet Extrusion Machine - Plastic recycling machine PPpe washing crushing drying line – WOOD-PLASTIC, The product will supply to all over the world, such as: Jakarta, belarus, Florence, we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

1, WARRANTY TERMS:

1.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

1.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

1.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

2, DELIVERY CONDITIONS:

2.1 DELIVERY CONDITION: FOB QINGDAO PORT.

2.2 DELIVERY TERM: WITHIN 60 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

2.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER CAN ARRANGE FOR SUPERVISION OF LOADING.

3, INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4, INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE.

If any interest to our machines, please kindly feel free to contact us:

Email: info@tongsanextruder.com info@wpcmachinery.com

Phone: 0086-13953226564

TEL:0086-532-82215318

Address: The West End And South Side Of Yangzhou Road,Jiaozhou City,Qingdao,China

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.

-

Factory Price For Pp Sheet Extruding Machine -...

-

Massive Selection for Cheap Bedroom Wooden Door...

-

OEM Factory for Plastic Pipe Fittings - PVC sh...

-

Cheapest Factory Sheet Production Line - Corru...

-

PriceList for Extrusion Machine For Medical - ...

-

Good Quality Pvc Edge Banding Sheet Making Mach...