Personlized Products Plastic Sheet Cutting Machine Suppliers - 110-450mm PP Pipe production line – HEGU Detail:

110-450mm PP pipe extrusion line, PP pipe production line, PP pipe making machine, PP pipe manufacturing machine, PP pipe equipment, PP pipe extruder, PP pipe extrusion machine

Feature of our PP pipe production line:

1,The main machine adopts screws specially used for polyolefin. Equipped with auto vacuum charger and auto constant temperature dryer hopper, it possesses features of high production, good plasticization and stable extruding.

2,Die heads of helical type and basket type are perfect for polyolefin, and can help to produce sound melting pressure, and improve the plasticization capacity. Meanwhile, stable material-flow and pressure grade can be guaranteed.

3, Advanced vacuum calibrating method improves the cleanliness and hardness of surface. Reasonable high-speed sprinkling cooling water tank guarantees the pipe quality and high speed stable extruding.

4,Caterpiller of the hauling machine adopts anti abrassion alloy material, which realizes stable traction, wide frequency adjustment range and long lifespan.

5,New generation auto dust-free cutting blade realizes smooth cutting secant, high precison and low noise.

Models of PP pipe production line:

| Model | SJ65/33 | SJ75/33 | SJ90/33 | SJ120/33 |

| Pipe diameter | 16-63mm | 75-250mm | 110-450mm | 315-630mm |

| Marking line | SJ30 | SJ30 | SJ30 | SJ30 |

| Output capacity | 100kg/h | 150-200kg/h | 300-450kg/h | 500-700kg/h |

Machine parts of our PP pipe production line

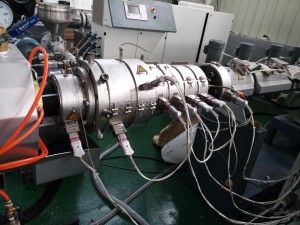

1, Main extruder: single screw extruder for PP pipe production line

2, co-extruder for PP pipe production line: SJ30 extruder for marking line

3, die head for PP pipe production line: different size may use different die head

4, vacuum cooling tank for PP pipe production line: 6 meter length

5, spraying water tank for PP pipe production line: 6 meter length, for big diameter, we may need to equip 2 sets or 3 sets of spraying water tank

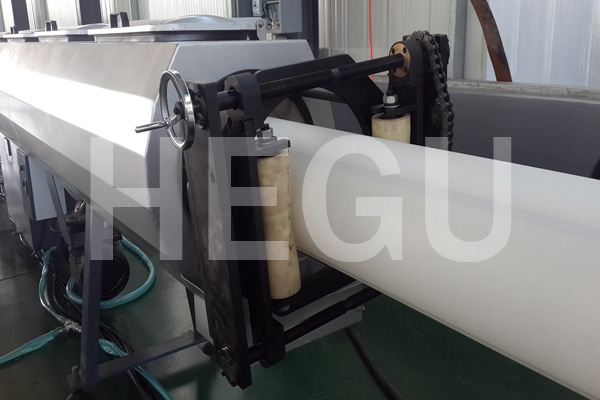

6, haul off machine for PP pipe production line: for different diameter, we may equip different type of haul off machine, such as double caterpillar type, three caterpillar type, four caterpillar type

7, cutting machine for PP pipe production line: high quality cutting machine for non-dust cutting

8. product stacker for PP pipe production line: 6 meter length

Product detail pictures:

Related Product Guide:

PVC Pipes Measurements

PVC Pipes – Types of PVC Pipes and Their Usage

We generally believe that one's character decides products' high quality, the details decides products' high-quality ,along with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Personlized Products Plastic Sheet Cutting Machine Suppliers - 110-450mm PP Pipe production line – HEGU, The product will supply to all over the world, such as: Lebanon, Swaziland, Oman, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

1, WARRANTY TERMS:

1.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

1.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

1.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

2, DELIVERY CONDITIONS:

2.1 DELIVERY CONDITION: FOB QINGDAO PORT.

2.2 DELIVERY TERM: WITHIN 60 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

2.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER CAN ARRANGE FOR SUPERVISION OF LOADING.

3, INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4, INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE.

If any interest to our machines, please kindly feel free to contact us:

Email: info@tongsanextruder.com info@wpcmachinery.com

Phone: 0086-13953226564

TEL:0086-532-82215318

Address: The West End And South Side Of Yangzhou Road,Jiaozhou City,Qingdao,China

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!

-

100% Original Factory Pvc Compound For Wire And...

-

Personlized Products Pvc Pipe Machine With Pric...

-

Free sample for Pvc Pipe Printing Machine - Pl...

-

Good User Reputation for Pe Pipe Extruder Machi...

-

High reputation Plastic Pipe Machine - Wood Pl...

-

Manufacturer of Forming Pipe Machine - Wood Pl...