1700mm PP mochini o etsang marako a mafahla: o sebelisetsoa ho etsa lakane e sekoti ea PP e sebelisetsoang ho etsa lebokose la polasetiki ea ho paka.

PC/PE/PP Hollow Grid Plate Extrusion Line,Mochini oa ho etsa lakane oa PP, PP lefahla leboteng lakane ho etsa mochine, PP paka lebokose tlhahiso line, PP corrugated lakane extrusion line.

Mochini ona oa ho etsa lipampiri tse peli tsa PP o hlokomela tlhahiso e tsoelang pele ea poleiti e sekoti ea PC/PE/PP, e sebetsang mokhabisong oa kaho, pokello ea lipapatso, le ho koala lerata tseleng e kholo hammoho le ho paka.PE/PP hollow grid plate ke sebaka se loketseng sa lebokose la pampiri ha ho etsoa lebokose la ho paka.E khetholloa ka boima bo bobebe, matla a phahameng, ho thibela letamo le ho thibela ho bola.Bophara ba lihlahisoa ke 1220-2100 mm, 'me botenya ke 2 mm-12 mm.

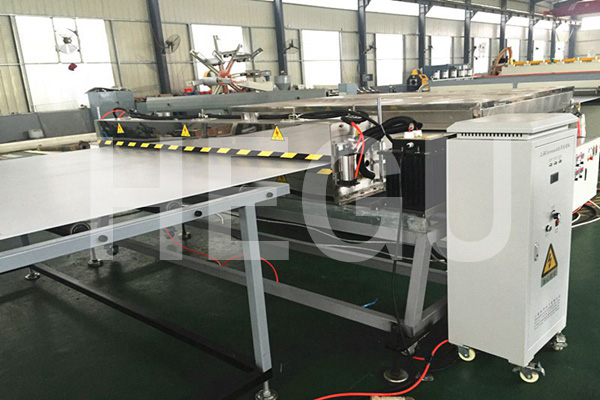

Lits'oants'o tsa mochini bakeng sa mochini o etsang marako a mafahla a PP:

1, Silo e kopanyang lisebelisoa bakeng sa mochini oa ho etsa pampiri ea mafahla ea PP: e sebelisetsoa ho kopanya lisebelisoa tsa PP ka ho tlatsa masterbatch le colorbatch.

2, Extruder bakeng sa mochini o etsang marako a mafahla a PP:Sekoti se entsoeng ka mokhoa o khethehileng le tsamaiso e tsoetseng pele ea ho laola e netefatsa palatalization e babatsehang, tlhahiso e phahameng le extruding e tsitsitseng.

Haeba moreki a batla ho sebelisa lisebelisoa tsa recyle, re ka boela ra hlomella mohala oa co-extrusion bakeng sa ho etsa letlapa le sekoti la PP, lesela le ka hare le ka sebelisa lisebelisoa tsa PP tse nchafalitsoeng, 'me lesela le kaholimo le ka sebelisa lisebelisoa tse ncha tsa PP.

3, hlooho le hlobo bakeng sa mochini oa ho etsa pampiri ea mafahla oa PP:re ka hlomella hlooho ea lefu le calibrator bakeng sa bophara bo fapaneng, joalo ka 1220mm, 1700mm, 2100mm,2300mm,2500mm.

Ho fetola skrine bakeng sa mochini oa ho etsa pampiri oa mafahla oa PP: Phetoho e potlakileng ea skrine ea sisteme ea hydraulic e netefatsa hore nako e khuts'oane ea ho fetoha ha skrini.Maemo a mabeli a kopantsoeng le sebopeho se khethehileng sa tiiso se tiisa ts'ebetso e tsitsitseng ea mochini o fetolang skrini.

Mould: Mould o sebelisa tšepe ea boleng bo holimo le sesebelisoa sa ho thothomela ho netefatsa hore esita le khatello ea phepelo e nang le tšusumetso molomong oa hlobo, le ketso e fapaneng ea sekotoana se tiisang botenya ba poleiti.

Tafole ea Vacuum calibrating bakeng sa mochini o etsang marako a mafahla a PP:Sistimi ea phapanyetsano ea mocheso le pholileng ea lebelo le potlakileng ho lekola sistimi e fapanyetsana hantle le ka tloaelo ka sistimi ea vacuum, e netefatsang ho nepahala ha maemo.Sistimi ea vacuum e na le li-subsystem tse peli tse ikemetseng 'me e' ngoe le e 'ngoe e na le mela e mengata e tsitsitseng e potolohang ea mofuta oa lintlha tse tharo.Ho sa le joalo, mohala o mong le o mong o na le sistimi e laolang vacuum le sistimi e bonts'a vacuum e hlokomelang boemo bo tsitsitseng ba vacuum holim'a poleiti.

Terekere bakeng sa PP mafahla leboteng ho etsa mochini ho etsa: Ho na le literekere tse peli.Ea pele ke matla a phahameng, karo-karolelano e phahameng ea ho fokotsa, mofuta oa li-roller tse ngata, ts'ebetso e tlaase ka lebelo le tlaase, ho hula ka holimo 'me e khona ho hula poleiti ho tloha tafoleng ea calibrating ka ho lekana le ka mokhoa o lumellanang.Ea bobeli e etselitsoe ho tlosa khatello ea kelello, 'me ho phaella moo e na le lisebelisoa tse fokotsang bohale ho netefatsa hore bophara bo nepahetseng le ho khaola ka boreleli ba metse.

Stress remover bakeng sa PP mafahla leboteng ho etsa mochine: The e tsoetseng pele khōlō sebaka conductive futhumatsang mode ka ka katleho tlosa khatello ea kelello poleiti le ho feta ntlafatsa plainness ea poleiti.

Mochini oa ho itšeha bakeng sa mochini o etsang letlapa la mafahla oa PP:Mokhoa o nepahetseng oa ho itšeha o tsitsitseng hang-hang le sistimi ea ho lahla ea othomathike e kopantsoeng le lehare le bohale la tšepe le hlokomela boleng bo phahameng ba ho itšeha.

Sehlahisoa sa ho qetela le ts'ebeliso e entsoeng ke mochini oa ho etsa pampiri ea mafahla oa PP

1, MELAO EA TIISETSO:

1.1 TIISETSO NAKO:LIKHOELI 12, HO TLOHA LETSATSI LA PELE LA MECHINA E SEBELISANG LEBOLONG LA BATHO BA BATHO.

1.2 MOREKISI O TLA FANA: LITŠEBELETSO LE LIKAROLO TSE SEKETSENG,TŠEBELETSO EA MAHALA KA NAKO EOHLE EA TIISETSO EA LIHLOOHO.

1.3 TŠEBELETSO EA BOPHELO:MOREKISI O LOKELA HO FANA KA TŠEBELETSO EA BOPHELO BA NAKO EA BOPHELO BA LITHO TSE REKIsitsoeng, MOREKI A LEFA LIKAROLO TSE HLOKANG KA MOR'A MELAO EA TIISETSO EA LIKHOELI 12.

2, MAEMO A HO PHELA:

2.1 BOEMO BA HO PHELA:FOB QINGDAO KOU.

2.2 NAKO EA HO FIHLELA:KA MATSATSI A 60 A HO SEBETSA KA MOR'A HO FUMANA TEFO E TSOHLE, MOREKISI O LOKELA HO TSEBISA MOREKI HORE A ETSE HLAHLOBO.MOREKISI O TSHWANETSE HO QETELA HO PAKA LITHO LE HO LOKELA HO THUSOA KA MATSATSI A 15 A HO SEBETSA KA MOR'A MOR'A MOREKISI A AMOHILE TEFO E FELETSENG.

2.3 TSAMAISO EA HO LOADING:MOREKI O TSHWANETSE HO TSEBISA MOREKI KA NAKO E LEBANG HO LAOA KA NAKO, MOREKI A KA HLOKELA HO HLOKOMELA HO LAOLWA.

3, HLAHLOBO:

HA MOCHINTŠI O QETILE, MOREKI O LOKELA HO TSEBISA MOREKI HO ETSA TLHAHLOBO PELE HO THUSOA, MOTHEKI O HLOMELA MOSEBETSI OA MOLEMO OA LITHO TSOHLE tse rekisitsoeng.MOREKISI O FIHLELA LITEHELO TSA TLHOKOMELISO BAKENG SA TLHOKOMELISO EA MACHINE.MOREKI O TLA TLA FEDKENG YA MOREKI HO TLA ETSA MOSEBETSI OA HLAHLOBO, KAPA MOREKI A KA ABELA KAROLO EFE EFE EA BORARO HO TLA FKKENG EA MORETSI HO TLA ETSA MOSEBETSI OA HLAHLOBO.

4, KOMISI EA HO KENYA LE LISEBETSI:

HAEBA MOREKI A HLOKA, MOREKI O TSHWANETSE HO ROMELA THIMI YA TECHNICIAN FACTORY YA MORKI HO KENYA LE HO LEKOLA MORA OHLE.

Haeba ho na le thahasello ho mechini ea rona, ka kopo ikutloe u lokolohile ho ikopanya le rona:

Lengolo-tsoibila:info@tongsanextruder.com info@wpcmachinery.com

Mohala: 0086-13953226564

TEL:0086-532-82215318

Aterese: The West End le South Side Of Yangzhou Road, Jiaozhou City, Qingdao, China